Artificial intelligence is fundamentally reshaping how engineers, designers, and scientists select materials for groundbreaking innovations, bringing unprecedented speed, accuracy, and possibilities to material science.

🔬 The Traditional Material Selection Challenge

For decades, material selection has been a painstaking process requiring extensive expertise, physical testing, and often years of trial and error. Engineers traditionally relied on material databases, handbooks, and their accumulated experience to identify suitable materials for specific applications. This conventional approach, while effective, presented significant limitations in terms of time consumption, cost, and the ability to explore the vast universe of potential material combinations.

The complexity of modern engineering challenges demands materials with increasingly sophisticated properties. From aerospace components that must withstand extreme temperatures to biomedical implants requiring perfect biocompatibility, the stakes have never been higher. Traditional methods struggle to keep pace with these evolving demands, creating a critical need for more advanced selection methodologies.

The Dawn of AI-Powered Material Science

Artificial intelligence has emerged as a transformative force in material selection, offering capabilities that were unimaginable just a few years ago. Machine learning algorithms can now process vast datasets containing information about millions of materials, their properties, performance characteristics, and real-world applications. This computational power enables researchers to identify optimal materials faster and more accurately than ever before.

The integration of AI into material science represents more than incremental improvement—it’s a paradigm shift. These intelligent systems can recognize patterns across multiple dimensions simultaneously, considering factors like mechanical properties, thermal behavior, chemical resistance, cost, availability, and environmental impact in ways that surpass human cognitive capabilities.

Machine Learning Models Revolutionizing Discovery

Neural networks and deep learning algorithms have proven particularly effective in predicting material properties based on compositional and structural data. These models learn from existing material databases, scientific literature, and experimental results to make increasingly accurate predictions about how new or modified materials will perform under various conditions.

Researchers at leading institutions have developed AI systems capable of predicting properties like tensile strength, electrical conductivity, and corrosion resistance with remarkable accuracy. Some systems achieve prediction accuracy rates exceeding 90%, dramatically reducing the need for expensive and time-consuming physical testing during the initial selection phase.

🚀 Accelerating Innovation Across Industries

The impact of AI-driven material selection extends across virtually every manufacturing and engineering sector. In the automotive industry, AI helps identify lightweight materials that maintain structural integrity while reducing vehicle weight and improving fuel efficiency. Electric vehicle manufacturers particularly benefit from AI’s ability to optimize battery materials for energy density, charging speed, and longevity.

Aerospace engineers leverage AI to discover materials capable of withstanding the extreme conditions of space travel while minimizing weight—a critical factor where every gram counts. Recent AI-assisted discoveries have led to new alloy compositions that offer superior performance at high altitudes and extreme temperatures.

Transforming Sustainable Material Development

Environmental sustainability has become a paramount concern in material selection, and AI excels at identifying eco-friendly alternatives to traditional materials. Machine learning algorithms can evaluate the complete lifecycle of materials, from extraction and processing to end-of-life recyclability, helping companies make environmentally responsible choices without sacrificing performance.

Several companies have used AI to develop bio-based materials and recyclable composites that match or exceed the performance of conventional petroleum-based materials. This capability is particularly valuable as industries face increasing pressure to reduce their carbon footprint and embrace circular economy principles.

Breaking Through the Complexity Barrier

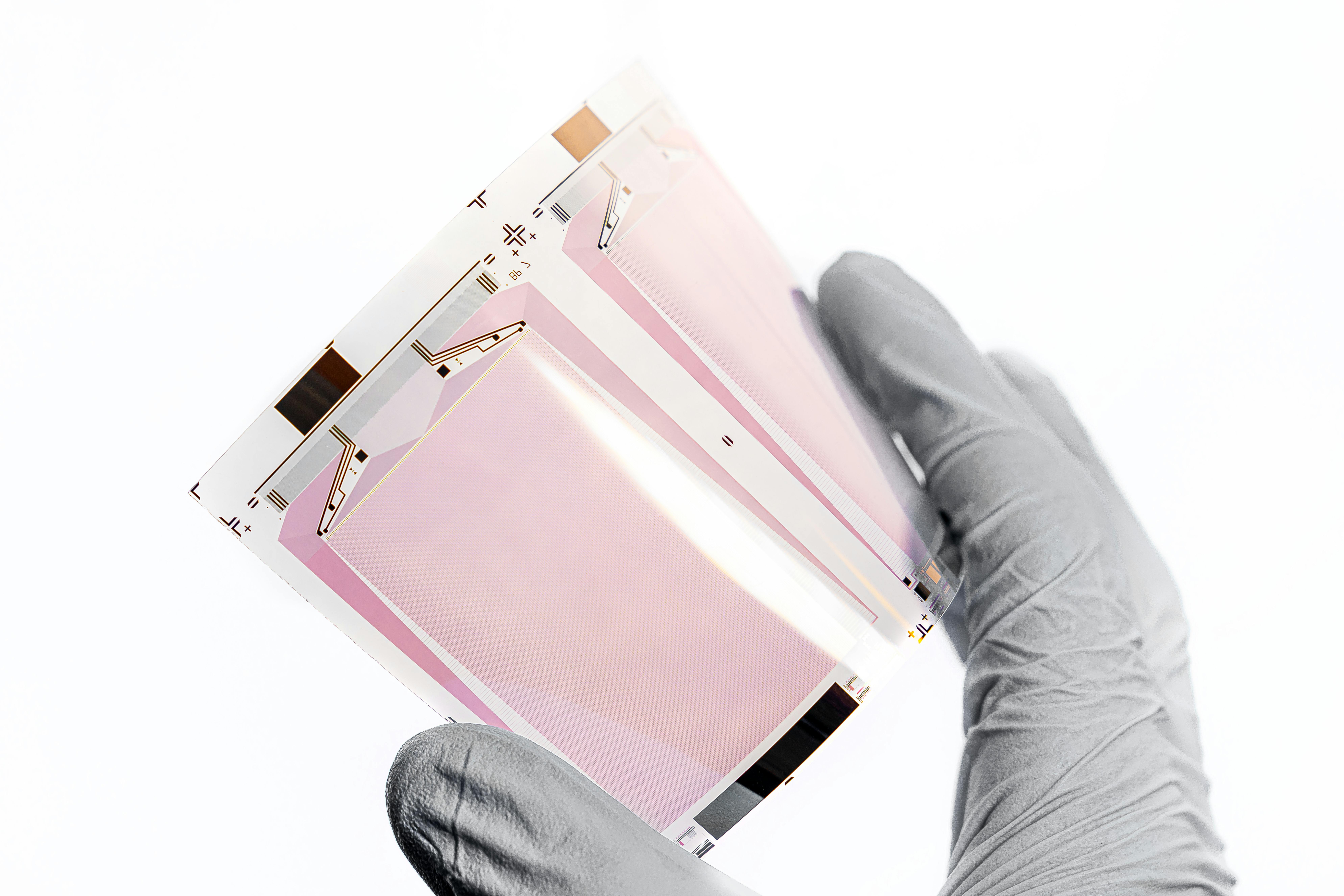

Modern applications often require materials with multiple, sometimes conflicting, properties. A smartphone component, for example, might need to be lightweight, durable, thermally conductive, electrically insulating, and aesthetically pleasing—all while remaining cost-effective to manufacture. Balancing these competing requirements challenges even experienced material engineers.

AI excels at multi-objective optimization, simultaneously evaluating thousands of potential materials against multiple criteria. Advanced algorithms can identify materials that represent the best compromise across all requirements, or even discover unexpected solutions that human intuition might overlook. This capability has proven invaluable in developing next-generation electronics, medical devices, and consumer products.

Predictive Performance Modeling

Beyond static property prediction, AI systems now model how materials will behave over time under various stress conditions. These predictive models simulate years of wear, environmental exposure, and operational stress in minutes, providing insights into long-term performance, degradation patterns, and maintenance requirements before a single prototype is manufactured.

This predictive capability significantly reduces development risks and costs. Companies can virtually test multiple material options under diverse scenarios, eliminating poor candidates early in the design process and focusing resources on the most promising solutions.

💡 Discovering Materials That Don’t Yet Exist

Perhaps the most exciting application of AI in material selection is its ability to suggest entirely new materials that have never been synthesized. Generative AI models can propose novel chemical compositions and structural arrangements predicted to exhibit desired properties, opening unprecedented possibilities for material innovation.

Research teams have successfully used AI to design new materials with specific target properties, which were then synthesized in laboratories and confirmed to perform as predicted. This approach effectively reverses the traditional discovery process—instead of finding applications for existing materials, scientists now define desired properties and let AI design materials to meet those specifications.

Accelerating Time-to-Market

The traditional material development cycle, from initial concept to commercial production, often spans 10-20 years. AI is compressing this timeline dramatically, with some projects achieving viable materials in just 2-3 years. This acceleration provides significant competitive advantages and enables faster responses to emerging market needs and technological opportunities.

Companies that embrace AI-driven material selection can iterate through design options more rapidly, test concepts virtually before committing to physical prototypes, and bring innovative products to market while competitors are still in early development stages.

Integration with Advanced Manufacturing Technologies

AI-powered material selection doesn’t exist in isolation—it integrates seamlessly with other digital manufacturing technologies. When combined with additive manufacturing (3D printing), AI can optimize not just material selection but also internal structures and geometries to maximize performance while minimizing material usage.

Digital twins—virtual replicas of physical products—incorporate AI-selected materials to simulate complete product lifecycles. Engineers can test how material choices affect overall system performance, identify potential failure modes, and optimize designs before manufacturing begins. This holistic approach reduces waste, improves reliability, and enhances product quality.

Real-Time Material Adaptation

Emerging AI systems can recommend material adjustments during manufacturing processes based on real-time sensor data. If environmental conditions change or quality metrics deviate from targets, AI algorithms can suggest composition modifications or processing parameter adjustments to maintain optimal results. This adaptive capability represents the next frontier in intelligent manufacturing.

🎯 Practical Implementation Strategies

Organizations looking to adopt AI-driven material selection should begin by assessing their current material databases and knowledge repositories. The quality and completeness of input data directly impact AI system effectiveness. Many companies start by digitizing historical testing data, material specifications, and performance records to create robust training datasets.

Successful implementation typically follows a phased approach. Initial projects often focus on specific material classes or applications where historical data is abundant and requirements are well-defined. As teams gain experience and confidence, they expand AI applications to more complex scenarios and exploratory projects.

Building Cross-Functional Teams

Effective AI-driven material selection requires collaboration between material scientists, data scientists, and domain experts. Material scientists provide essential knowledge about material behavior and application requirements. Data scientists develop and refine algorithms. Domain experts ensure that AI recommendations align with practical manufacturing constraints, regulatory requirements, and business objectives.

Companies achieving the greatest success with AI material selection invest in training programs that help material engineers understand AI capabilities and limitations, while also educating data scientists about material science fundamentals. This shared understanding facilitates productive collaboration and more effective tool development.

Overcoming Implementation Challenges

Despite its tremendous potential, AI-driven material selection faces several challenges. Data availability and quality remain significant concerns, particularly for newer material classes where limited experimental data exists. Proprietary information barriers can restrict access to valuable datasets, forcing organizations to develop solutions using incomplete information.

Validation represents another critical challenge. While AI predictions may be mathematically sound, physical verification remains essential, particularly for safety-critical applications. Regulatory agencies and industry standards bodies are still developing frameworks for accepting AI-generated material recommendations, requiring companies to maintain traditional validation processes alongside AI tools.

Addressing the Black Box Problem

Many powerful AI models operate as “black boxes,” providing accurate predictions without clear explanations of their reasoning. This opacity concerns engineers who need to understand why specific materials are recommended. Recent advances in explainable AI are addressing this limitation, developing systems that provide transparent reasoning alongside their recommendations.

Interpretable AI models help engineers build confidence in AI recommendations and identify potential issues before they become problems. These systems highlight which material properties most influence their predictions, allowing experts to verify that recommendations align with established material science principles.

🌐 The Future Landscape of Material Innovation

As AI technologies continue advancing, their impact on material selection will only intensify. Quantum computing promises to enable even more sophisticated material simulations, potentially predicting properties at the atomic level with unprecedented accuracy. Integration with robotics and automated laboratories will enable AI systems to not only recommend materials but also autonomously synthesize and test them.

The democratization of AI tools is making advanced material selection capabilities accessible to smaller organizations and individual researchers. Cloud-based platforms offer sophisticated AI material selection services without requiring massive computational infrastructure or extensive data science expertise, leveling the playing field and accelerating innovation across the entire industry.

Collaborative Global Material Intelligence

Future material selection systems will likely operate as collaborative networks, sharing anonymized data and insights across organizations and borders. Blockchain technologies could enable secure sharing of material performance data while protecting proprietary information, creating ever-more-comprehensive knowledge bases that benefit all participants.

International standardization efforts are working to establish common data formats, testing protocols, and AI model validation procedures. These standards will facilitate data sharing and enable AI systems trained by different organizations to work together, creating a truly global material intelligence network.

Empowering the Next Generation of Innovators

Educational institutions are incorporating AI-driven material selection into engineering curricula, preparing the next generation of materials scientists and engineers to leverage these powerful tools from the beginning of their careers. Students learn not just traditional material science but also computational methods, data analytics, and AI fundamentals.

This educational shift is producing engineers who think differently about material selection—viewing it as an optimization problem amenable to computational solutions rather than solely an experience-based art. This new perspective will drive further innovation as these professionals enter industry and apply AI tools in novel ways their predecessors never imagined.

🎊 Embracing the Material Revolution

The transformation of material selection through artificial intelligence represents one of the most significant advances in engineering practice in decades. By enabling faster discovery, more accurate predictions, and exploration of vastly larger material spaces, AI is fundamentally changing what’s possible in product design and manufacturing.

Organizations that embrace these technologies position themselves at the forefront of innovation, capable of developing superior products more quickly and efficiently than competitors relying solely on traditional methods. The question is no longer whether to adopt AI-driven material selection, but how quickly and effectively organizations can integrate these tools into their development processes.

As AI continues evolving and improving, the synergy between human expertise and machine intelligence will unlock material innovations that seem impossible today. From sustainable alternatives to environmental pollutants to advanced materials enabling breakthrough technologies in energy, medicine, and transportation, AI-powered material selection is creating a future limited only by our imagination and willingness to embrace new approaches to age-old challenges.

The revolution in material selection is not coming—it’s already here, transforming how we create, innovate, and build the products and infrastructure that shape our world. The organizations and individuals who recognize this transformation and act decisively will lead the next wave of technological advancement, powered by the perfect partnership of human creativity and artificial intelligence.

Toni Santos is an architecture and sensory-design researcher exploring how built environments, material systems, and human perception shape health, wellbeing, and experience. Through his studies on environmental psychology, healing interior spaces, and multisensory design, Toni examines how architecture can be a catalyst for renewal, presence, and connection. Passionate about light, sound, colour and sustainable materials, Toni focuses on how design choices influence emotion, cognition, and embodiment in everyday life. His work highlights the intersection of sustainability and sensory intelligence — guiding architects and creators toward spaces that nurture the human spirit. Blending architecture, sensory science, and ecological design, Toni writes about the human side of space — helping readers understand how environments feel, heal and transform. His work is a tribute to: The power of built space to restore and uplift The fusion of material, perception and wellbeing The vision of architecture as a living, human-centred system Whether you are a designer, researcher, or space-creator, Toni Santos invites you to explore architecture through the lens of sensory wellbeing — one room, one material, one experience at a time.